OSHA requires employers to evaluate workplaces to determine if there are any respiratory hazards present.  If respiratory hazards are found, then employers are responsible for If respiratory hazards are found, then employers are responsible for

- Providing a written program with workplace-specific procedures,

- Identifying a qualified individual to oversee the program,

- Determining respiratory hazards in the workplace,

- Providing medical evaluations to employees required to wear respirators,

- Providing training to employees, and

- Fit-testing employees annually.

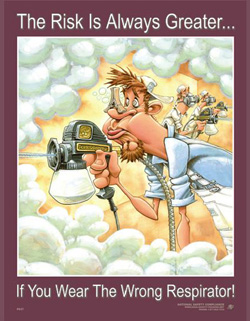

When a Respiratory Protection Program is required, the next task is to determine what type of respirator is needed. First, evaluate any chemicals by reviewing the material safety data sheets, evaluating the level of exposure, and reviewing regulatory requirements. Additionally, evaluate the respirator’s limitations to help determine if adequate protection will be provided to the employee.

OSHA defines the following as forms of respiratory hazards that may be present in the workplace:

- Dusts and fibers - solid particles that are formed or generated from solid materials through mechanical processes such as crushing, grinding, drilling, abrading, or blasting. Examples are lead, silica, and asbestos.

- Fumes - solid particles that are formed when a metal or other solid vaporizes and the molecules condense (or solidify) in cool air. Examples are metal fumes from smelting or welding. Fumes also may be formed from processes such as plastic injection or extrusion molding.

- Mists - tiny droplets of liquid suspended in the air. Examples are oil mists produced from lubricants used in metal cutting operations, acid mists from electroplating, and paint spray mist from spraying operations.

- Gases - materials that exist as individual molecules in the air at room temperature. Examples are welding gases, such as acetylene and nitrogen, and carbon monoxide produced from internal combustion engines.

- Vapors - the gaseous forms of substances that are normally in the solid or liquid state at room temperature and pressure. They are formed by evaporation. Most solvents produce vapors. Examples include toluene and methylene chloride.

- Biological hazards include bacteria, viruses, fungi, and other living organisms that can cause acute and chronic infections if inhaled. Examples include Legionnaire’s Disease, flour, and animal products (dander, excreta).1Understanding the physical form of the respiratory hazard will help determine the type of respirator needed.

The two types of respirators are air-purifying and air-supplying. Air-purifying respirators work by filtering particles or chemicals from the air. These respirators are known as particulate respirators, gas mask/chemical cartridge respirators, and powered air-purifying respirators (PAPR). Air-supplying respirators work by supplying clean air to the wearer from an outside source. These respirators are Self-Contained Breathing Apparatus (SCBA) and supplied-air respirators.

| Texas America Safety Company |

| 4400 Danhil Drive |

| Brownwood, TX 76801 |

| |

| Toll Free 1-800-646-5346 |

| Outside US 1-325-646-5346 |

| Local 325-646-5346 |

| Fax 1-325-646-3790 |

| sales@tasco-safety.com |

|

If respiratory hazards are found, then employers are responsible for

If respiratory hazards are found, then employers are responsible for